A polymer compounding company is an enterprise specializing in the production of polymer compounds. Polymer compounds are materials made by combining basic polymers with additives, fillers or other chemicals in order to achieve specific properties or improve performance for certain applications.

These companies operate in the plastics and polymer materials sector and supply a wide range of customized polymer composites or formulations to meet specific customer requirements or for use in particular industries.

The polymers used to produce the compounds can be virgin or recycled, from production waste, post-consumer waste or both.

Recycled raw materials are used to produce a variety of products with different applications: packaging, construction, automotive and many others.

Compounding companies have to choose the materials best suited to their customers' needs. Each material has its own unique characteristics and applications.

The activities of a polymer compounding company may include:

1) Selection of base polymers: The company chooses the base polymers, such as polyethylene (PE), polypropylene (PP), polycarbonate (PC), polystyrene (PS), thermoplastic polyurethane (TPU), polylactic acid (PLA) and others, based on the characteristics required for the final compound.

2) Addition of additives: Chemical additives such as thermal stabilizers, antioxidants, flame retardants, reinforcing agents, lubricating agents and more are incorporated to improve the mechanical, thermal or chemical properties of the material.

3) Incorporation of fillers: Fillers such as glass fibers, talc, mica or other materials are added to increase mechanical strength, reduce costs or modify other characteristics of the compound.

4) Designing customized formulations: Compounding companies work in collaboration with customers to design polymer compounds specific to their applications or needs.

5) Compounding process: Specialized equipment is used to mix and compact the components to obtain the final polymer compound.

Compounding companies help reduce the environmental impact of plastics by reusing recycled raw materials to produce new products. There are numerous examples of compounders that have helped improve the performance of recycled plastics and have enabled structured companies to start using recycled plastics successfully.

Thanks to the work of these companies, recycled plastic is becoming increasingly competitive with virgin plastic. This has enabled structured companies to successfully adopt recycled plastic in their production processes, replacing it without compromising the quality of the final product.

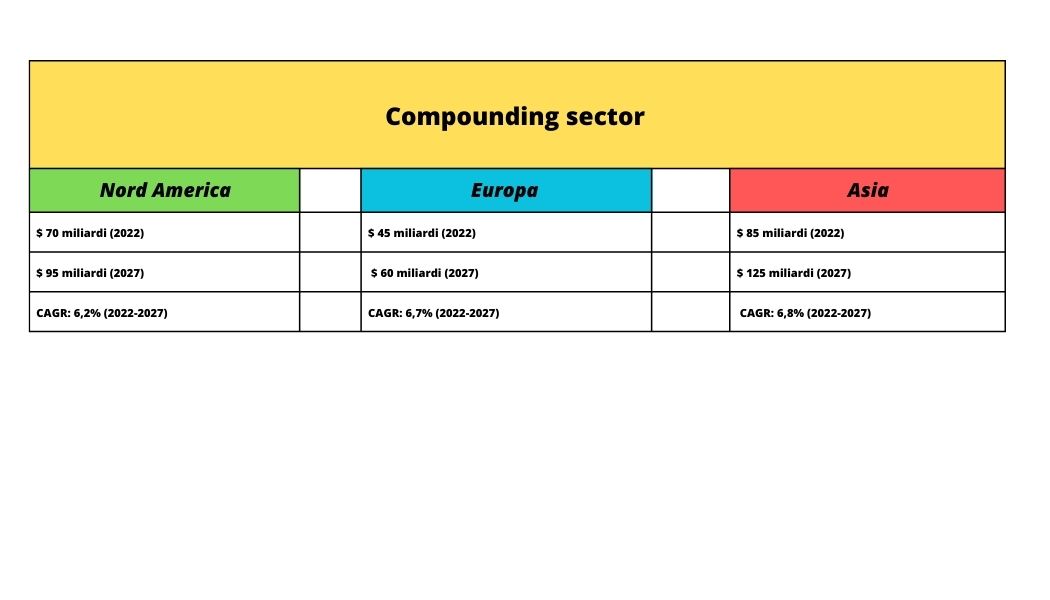

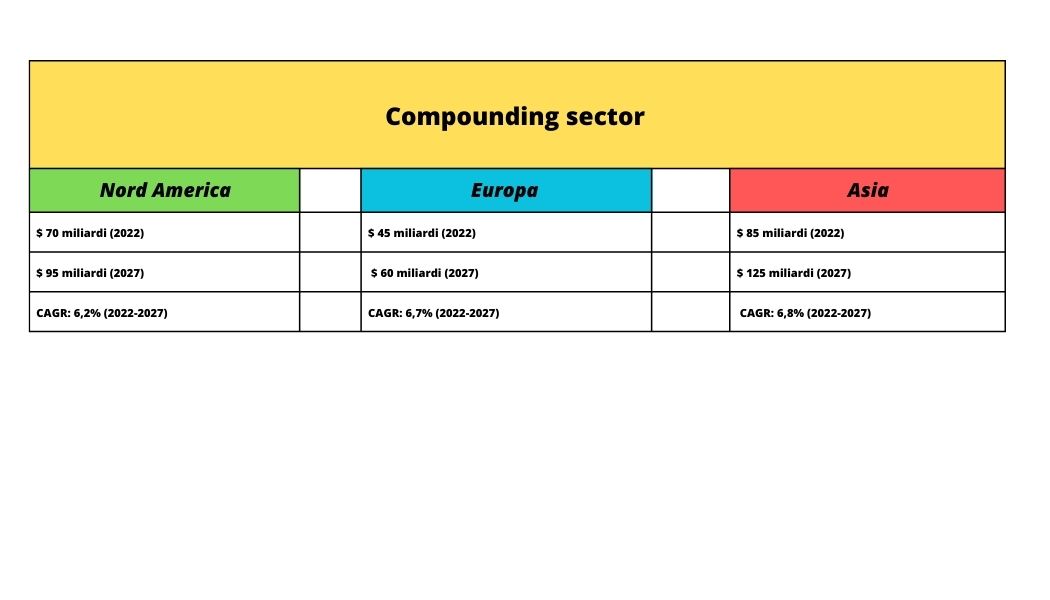

The compounding market is growing strongly. It was valued at $200 billion in 2022 and is expected to reach $280 billion by 2027, with a compound annual growth rate (CAGR) of 6.5% from 2022 to 2027.

The main levers for the success of the compounding industry in the future will be:

The growing demand for sustainable plastic products;

The increase in the number of companies seeking to reduce their environmental impact;

The development of new technologies that enable the production of more sustainable plastics.

Here are some figures on the growth of the bioplastics and thermoplastic elastomers market.

Compounding companies are always looking for new recycled materials and new technologies to improve their products.

In such an innovative context, it is important to set rules and modus operandi so that the risks associated with material shortages or the timing of tests to be carried out to ensure the production performance of a recycled material are managed correctly.

Gianeco has been working for 10 years with compounders specializing in bioplastics and thermoplastic elastomers. From this close collaboration comes a vademecum of useful tips for compounding companies:

1. Focus on quality: The quality of polymeric compounds is crucial for customer satisfaction and company reputation. Implement strict quality controls during the production process to ensure product consistency and reliability.

2. Choose reliable suppliers of recycled polymers: supplier selection is critical to ensure material quality and consistency, comply with regulations and promote sustainability. Assessing suppliers' technical expertise, certifications and past performance is very important for effective collaboration and a stable flow of high quality materials.

3. Invest in infrastructure and technology: Keeping the company abreast of modern technology and investing in state-of-the-art equipment to improve the efficiency of the compounding process.

4. Establish partnerships with customers: Work closely with customers to understand their specific needs and provide tailor-made solutions. Effective communication and constant feedback are key to maintaining a strong relationship and gaining valuable information for continuous product improvement.

5. Develop technical skills: Maintain a team of professionals with solid technical skills in the field of polymers and compounding. This makes it possible to meet technical challenges and provide high-level technical support to customers.

6. Investing in research and development: Keeping abreast of new technologies, material developments and market needs is essential. Investing in research and development makes it possible to improve existing polymeric compounds, develop new innovative formulations and offer customized solutions to customers.

7. Environmental sustainability: Consider the environmental impact of compounding products and processes. Adopting sustainable practices can be a competitive advantage, especially in an increasingly sustainability-conscious market.

8. Communication and marketing: Effectively communicate the benefits and characteristics of your polymeric compounds. Investing in marketing strategies to make the company and its products known can attract new customers and consolidate the company's reputation.

Gianeco has been active in the recycled plastics market for more than 10 years. Its knowledge of the market, sector trends and the needs of companies approaching recycled material make Gianeco an excellent partner.

We have identified 5 reasons that make Gianeco a reliable partner:

1.Reduction of environmental impact: the recycled plastic material produced and distributed by Gianeco has a composition for a minimum recycled content of 95%. Therefore, the use of these materials reduce the environmental impact of plastic, reducing the amount of plastic that is disposed of in landfills or in the environment;

2. Cost savings: recycled plastics are cheaper than virgin plastics;

3. Material quality: Gianeco's recycled polymers are carefully selected, processed and tracked to ensure high performance of the final compound;

4. Variety of materials: Gianeco offers a wide variety of colours, types and shapes of recycled polymers, which may be more suitable for manufacturers' needs;

5. Greater sustainability: producers of recycled plastics are more sustainable than producers of virgin plastics, as they use less energy and give new life to plastic waste.

Schedule an initial consultation call with Gianeco today.email: info@gianeco.com

phone: +39 0119370420A polymer compounding company is an enterprise specializing in the production of polymer compounds. Polymer compounds are materials made by combining basic polymers with additives, fillers or other chemicals in order to achieve specific properties or improve performance for certain applications.

These companies operate in the plastics and polymer materials sector and supply a wide range of customized polymer composites or formulations to meet specific customer requirements or for use in particular industries.

The polymers used to produce the compounds can be virgin or recycled, from production waste, post-consumer waste or both.

Recycled raw materials are used to produce a variety of products with different applications: packaging, construction, automotive and many others.

Compounding companies have to choose the materials best suited to their customers' needs. Each material has its own unique characteristics and applications.

The activities of a polymer compounding company may include:

1) Selection of base polymers: The company chooses the base polymers, such as polyethylene (PE), polypropylene (PP), polycarbonate (PC), polystyrene (PS), thermoplastic polyurethane (TPU), polylactic acid (PLA) and others, based on the characteristics required for the final compound.

2) Addition of additives: Chemical additives such as thermal stabilizers, antioxidants, flame retardants, reinforcing agents, lubricating agents and more are incorporated to improve the mechanical, thermal or chemical properties of the material.

3) Incorporation of fillers: Fillers such as glass fibers, talc, mica or other materials are added to increase mechanical strength, reduce costs or modify other characteristics of the compound.

4) Designing customized formulations: Compounding companies work in collaboration with customers to design polymer compounds specific to their applications or needs.

5) Compounding process: Specialized equipment is used to mix and compact the components to obtain the final polymer compound.

Compounding companies help reduce the environmental impact of plastics by reusing recycled raw materials to produce new products. There are numerous examples of compounders that have helped improve the performance of recycled plastics and have enabled structured companies to start using recycled plastics successfully.

Thanks to the work of these companies, recycled plastic is becoming increasingly competitive with virgin plastic. This has enabled structured companies to successfully adopt recycled plastic in their production processes, replacing it without compromising the quality of the final product.

The compounding market is growing strongly. It was valued at $200 billion in 2022 and is expected to reach $280 billion by 2027, with a compound annual growth rate (CAGR) of 6.5% from 2022 to 2027.

The main levers for the success of the compounding industry in the future will be:

The growing demand for sustainable plastic products;

The increase in the number of companies seeking to reduce their environmental impact;

The development of new technologies that enable the production of more sustainable plastics.

Here are some figures on the growth of the bioplastics and thermoplastic elastomers market.

Compounding companies are always looking for new recycled materials and new technologies to improve their products.

In such an innovative context, it is important to set rules and modus operandi so that the risks associated with material shortages or the timing of tests to be carried out to ensure the production performance of a recycled material are managed correctly.

Gianeco has been working for 10 years with compounders specializing in bioplastics and thermoplastic elastomers. From this close collaboration comes a vademecum of useful tips for compounding companies:

1. Focus on quality: The quality of polymeric compounds is crucial for customer satisfaction and company reputation. Implement strict quality controls during the production process to ensure product consistency and reliability.

2. Choose reliable suppliers of recycled polymers: supplier selection is critical to ensure material quality and consistency, comply with regulations and promote sustainability. Assessing suppliers' technical expertise, certifications and past performance is very important for effective collaboration and a stable flow of high quality materials.

3. Invest in infrastructure and technology: Keeping the company abreast of modern technology and investing in state-of-the-art equipment to improve the efficiency of the compounding process.

4. Establish partnerships with customers: Work closely with customers to understand their specific needs and provide tailor-made solutions. Effective communication and constant feedback are key to maintaining a strong relationship and gaining valuable information for continuous product improvement.

5. Develop technical skills: Maintain a team of professionals with solid technical skills in the field of polymers and compounding. This makes it possible to meet technical challenges and provide high-level technical support to customers.

6. Investing in research and development: Keeping abreast of new technologies, material developments and market needs is essential. Investing in research and development makes it possible to improve existing polymeric compounds, develop new innovative formulations and offer customized solutions to customers.

7. Environmental sustainability: Consider the environmental impact of compounding products and processes. Adopting sustainable practices can be a competitive advantage, especially in an increasingly sustainability-conscious market.

8. Communication and marketing: Effectively communicate the benefits and characteristics of your polymeric compounds. Investing in marketing strategies to make the company and its products known can attract new customers and consolidate the company's reputation.

Gianeco has been active in the recycled plastics market for more than 10 years. Its knowledge of the market, sector trends and the needs of companies approaching recycled material make Gianeco an excellent partner.

We have identified 5 reasons that make Gianeco a reliable partner:

1.Reduction of environmental impact: the recycled plastic material produced and distributed by Gianeco has a composition for a minimum recycled content of 95%. Therefore, the use of these materials reduce the environmental impact of plastic, reducing the amount of plastic that is disposed of in landfills or in the environment;

2. Cost savings: recycled plastics are cheaper than virgin plastics;

3. Material quality: Gianeco's recycled polymers are carefully selected, processed and tracked to ensure high performance of the final compound;

4. Variety of materials: Gianeco offers a wide variety of colours, types and shapes of recycled polymers, which may be more suitable for manufacturers' needs;

5. Greater sustainability: producers of recycled plastics are more sustainable than producers of virgin plastics, as they use less energy and give new life to plastic waste.

Schedule an initial consultation call with Gianeco today.email: info@gianeco.com

phone: +39 0119370420