Customized compounds of recycled thermoplastic elastomers: who can benefit from them and why rely on Gianeco?

Recycled thermoplastic elastomers (R-TPE) are versatile materials that can be used in a variety of applications.

Customized R-TPE compounds can be utilized by a variety of companies and organizations, including:

Manufacturing companies: Manufacturing companies often use customized compounds to create new materials or products. Custom compounds can be used to enhance material properties or to create products with specific characteristics.

Companies producing industrial items, such as components for automotive, electronics, or construction, can benefit from customized compounds of recycled thermoplastic elastomers. These materials can be tailored to production specifications, offering optimal mechanical, thermal, or aesthetic properties.

R-TPE can be used to create a variety of products, including toys, sports items, and home accessories. They are durable, comfortable, and can be customized to meet specific customer needs.

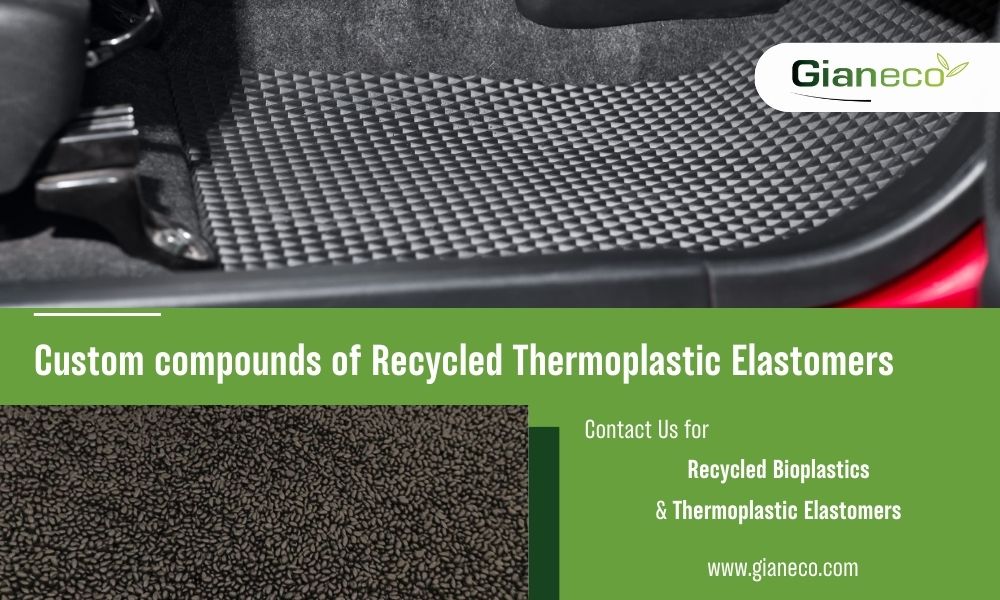

R-TPE can be used to create automotive components, such as seals, bumpers, and mats. They are wear-resistant and weather-resistant and can be recycled again.

Chemical companies: Chemical companies often use customized compounds to develop new chemical products. Custom compounds can be used to enhance the performance of chemical products or to create new ones with specific properties.

Some examples of companies using recycled TPE compounds:

The automotive company BMW uses a recycled TPE compound to produce standard car mats. This compound is made with 50% recycled material and offers the same performance as virgin TPE mats.

The sports equipment company Nike uses a recycled TPE compound to produce yoga mats. Among the best-known products is Nike Mastery. Made with at least 20% recycled materials, it is a blend of thermoplastic elastomers (TPE) and natural rubber, with a stone effect (read on to learn more about the most common materials used for yoga mats). TPE material helps reduce odor formation and weight grams, while natural rubber provides a fresh touch sensation and improves grip.

Adidas Parley: Adidas has collaborated with Parley for the Oceans to create sports shoes using recycled filaments from plastic recovered from the oceans. Although not exclusively thermoplastic elastomers, this project represents a tangible commitment to using recycled materials in sports footwear.

Tesla and battery recycling: Tesla, in the context of electric vehicle batteries, is adopting recycling practices for materials, including the recovery of thermoplastic elastomers present in various components such as seals and sealants within the batteries.

Why choose Gianeco?

Gianeco is a leading company in the production of customized compounds. The company offers a wide range of services, including:

Recycling process control: Gianeco's decades of experience facilitate the optimization of the recycling process to ensure material uniformity;

Strategic collaborations: Over the years, Gianeco has developed partnerships with manufacturing companies in various sectors to recover production waste and give it new life. Thanks to this network, more and more client companies have the opportunity to adopt recycled materials in their production processes, replacing virgin materials with more sustainable solutions without compromising the quality of the final product;

Formulation flexibility: Gianeco can adapt the composition of its compounds to meet specific requirements, such as wear resistance, flexibility, weather resistance, or other criteria necessary for the final application;

Quality control: Gianeco is committed to ensuring the quality of its products. The company has a rigorous quality control system that ensures its compounds meet the necessary standards for that specific production;

Commitment to sustainability: Gianeco's priority is the production of sustainable materials. Relying on Gianeco for customized compounds allows companies to demonstrate their commitment to environmental responsibility and reducing environmental impact.

Market trends for the compounding sector

Gianeco's experience allows it to anticipate some market trends for the compounding sector. In particular:

Growing demand for sustainable materials: Globally, there has been increasing demand from consumers and companies for sustainable materials with low environmental impact;

Increased environmental awareness: Increasing awareness of issues related to plastic pollution and climate change has prompted companies to seek sustainable alternatives to traditional plastics;

Greater attention to the circular economy: The market is becoming increasingly aware of the importance of the circular economy, which will lead to increased production and supply of recycled material, including recycled thermoplastic elastomers.

Technological innovations: The compounding industry continues to invest in new technologies and processes to improve material quality and optimize formulations. These innovations enable the production of increasingly high-performance and competitive compounds on the market.

Increased and diversified applications: Recycled thermoplastic elastomer compounds are finding increasingly diverse applications in various industrial sectors, including packaging, automotive, electronics, toys, and consumer goods.

Why rely on Gianeco?

Customized compounds can be a valuable resource for companies and organizations in any sector.

Gianeco is a leading company in the production of customized compounds and offers a wide range of products and related services to help companies meet their needs.